Aerofoil morphing by MCF actuators

The ability to change the shape of an aerofoil allows adapting it to different flow conditions and is typically used for improving the performance of aircraft wings. Morphing techniques have been explored to seamlessly change the shape of aerofoils between different geometries. A major difficulty in their implementation is represented by the size, weigh, complexity, and power

demanded by appropriate actuators (hydraulic, pneumatic, electric motors, or even some smart materials like

shape-memory alloys).

From a system-integration point of view the performance increase offered by the morphing

must out-weight its associated penalties.

|

|

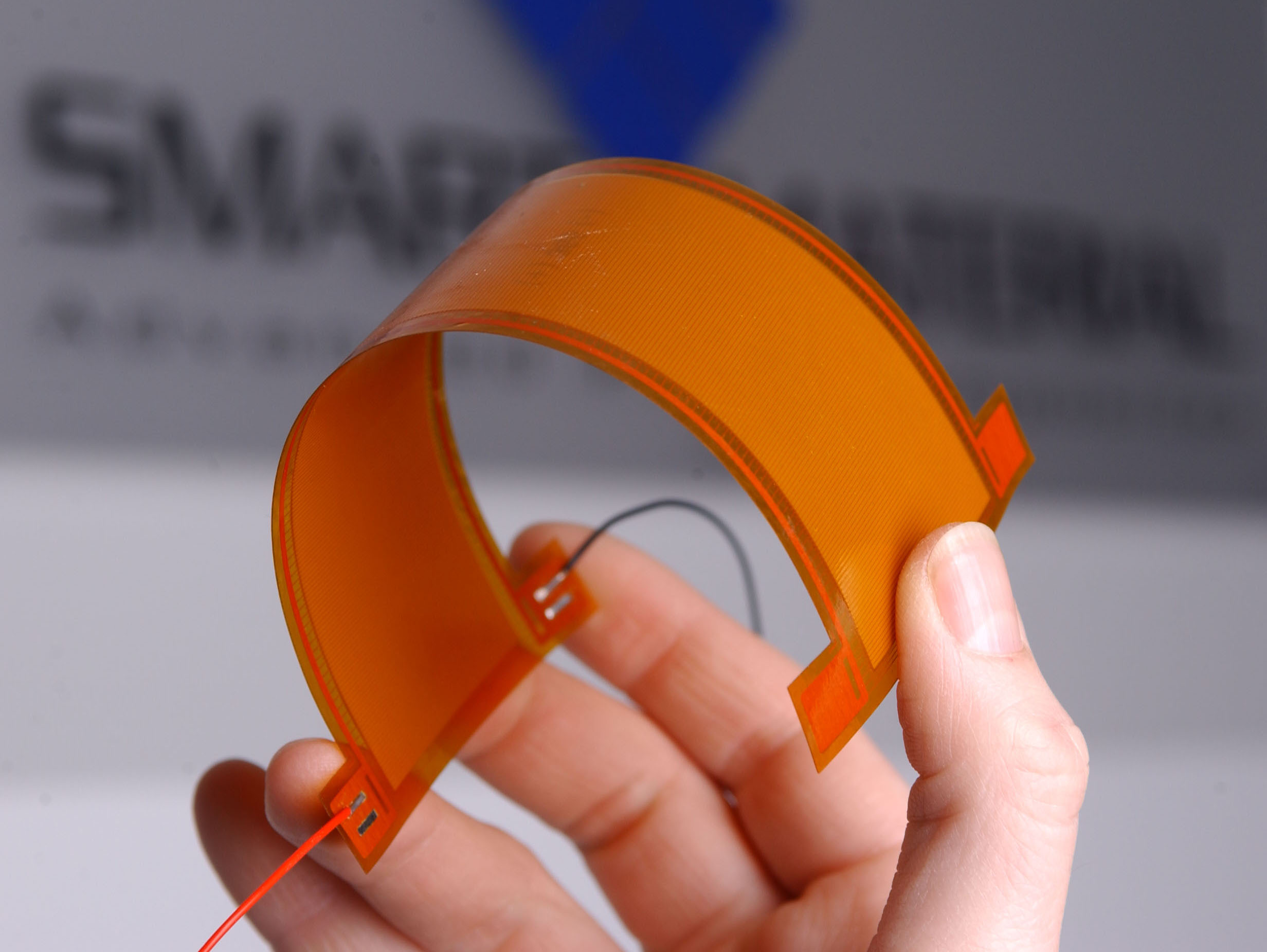

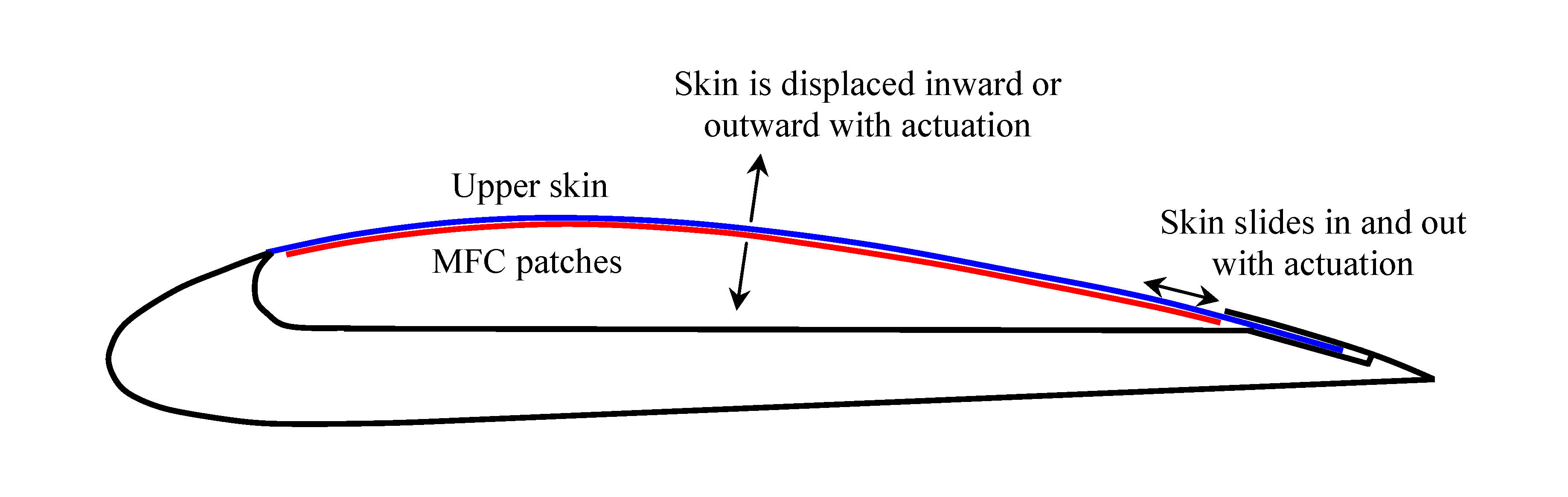

| Figure 1: MFC actuator [image courtesy of Smart Material Corp.]. |

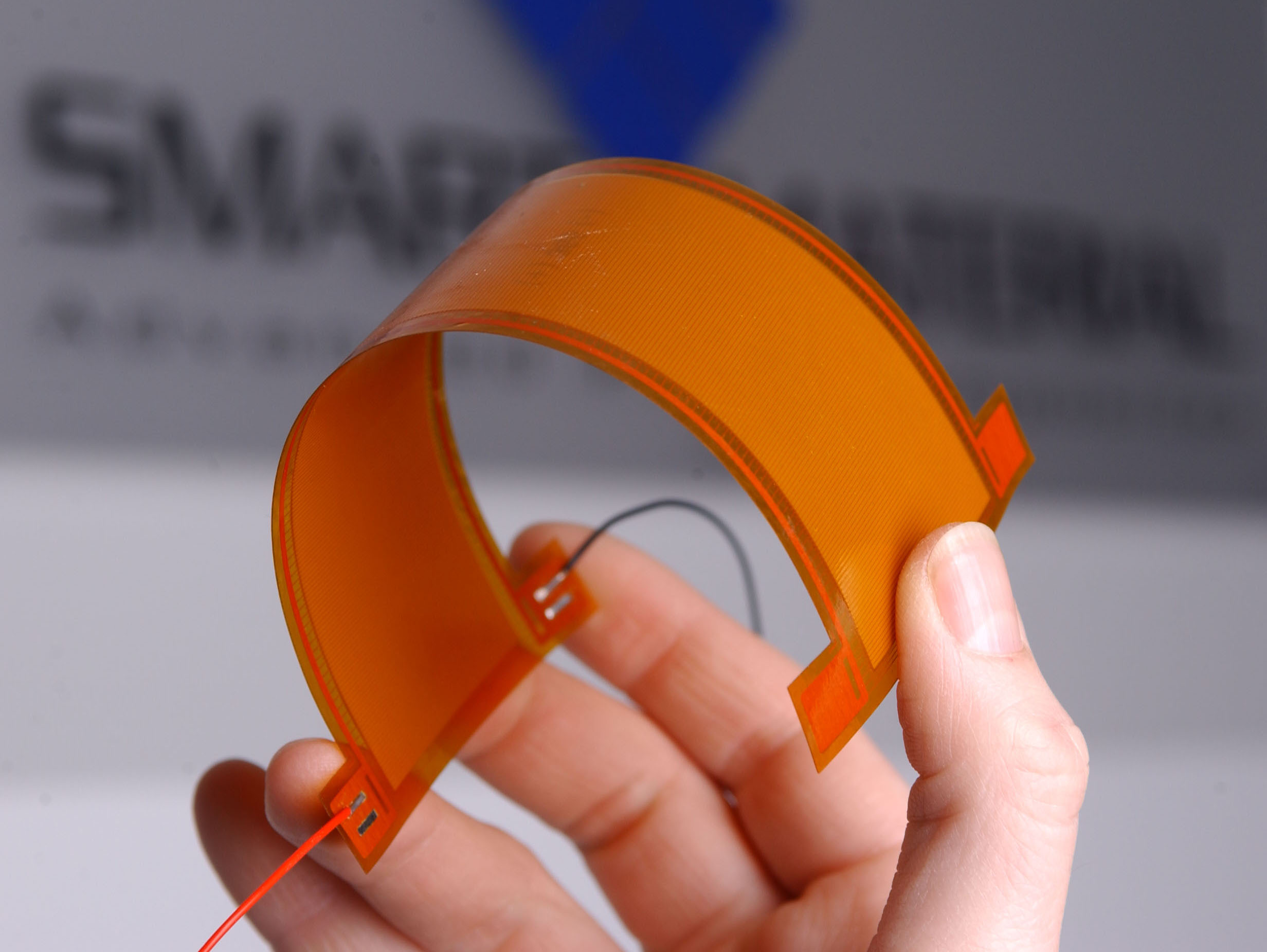

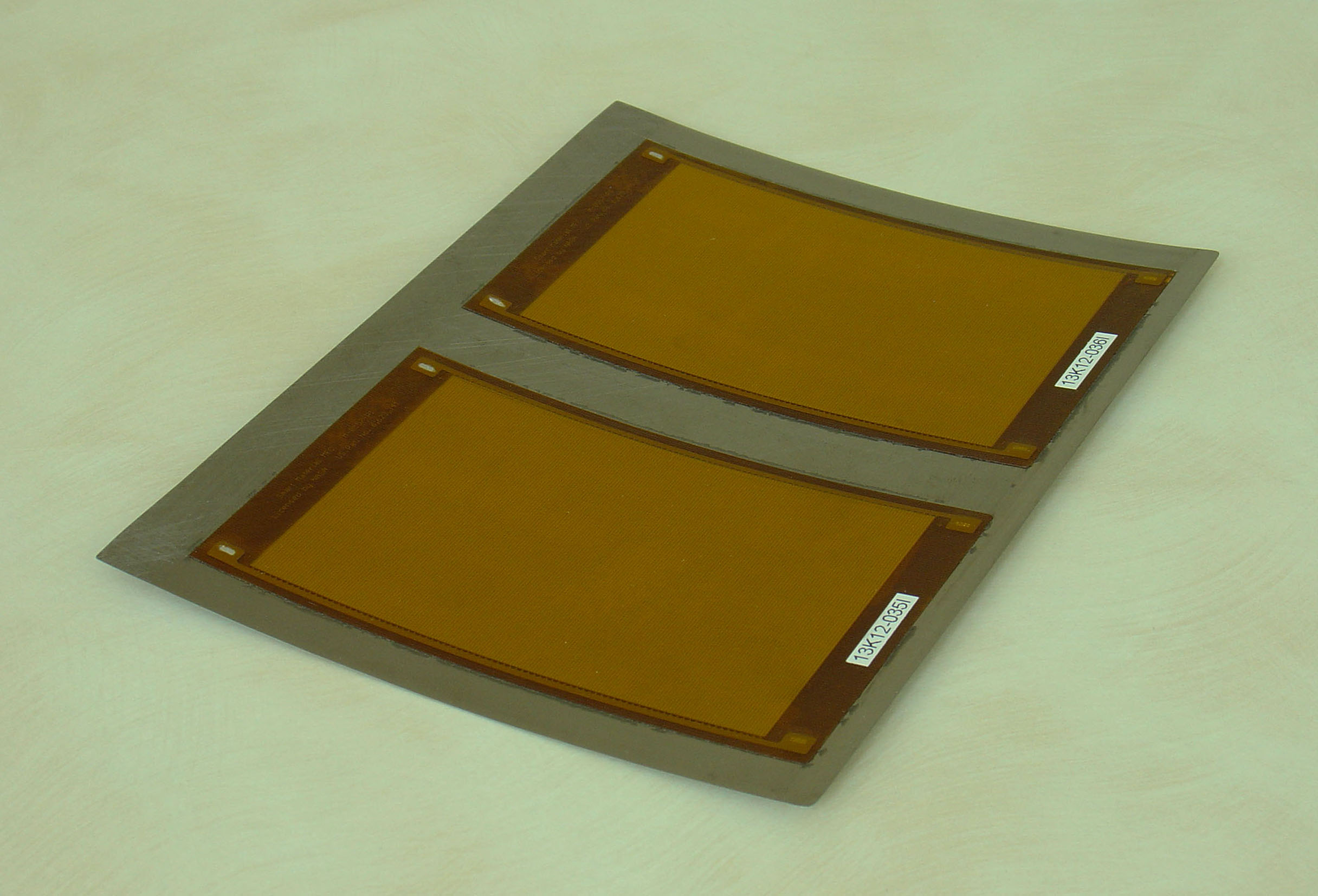

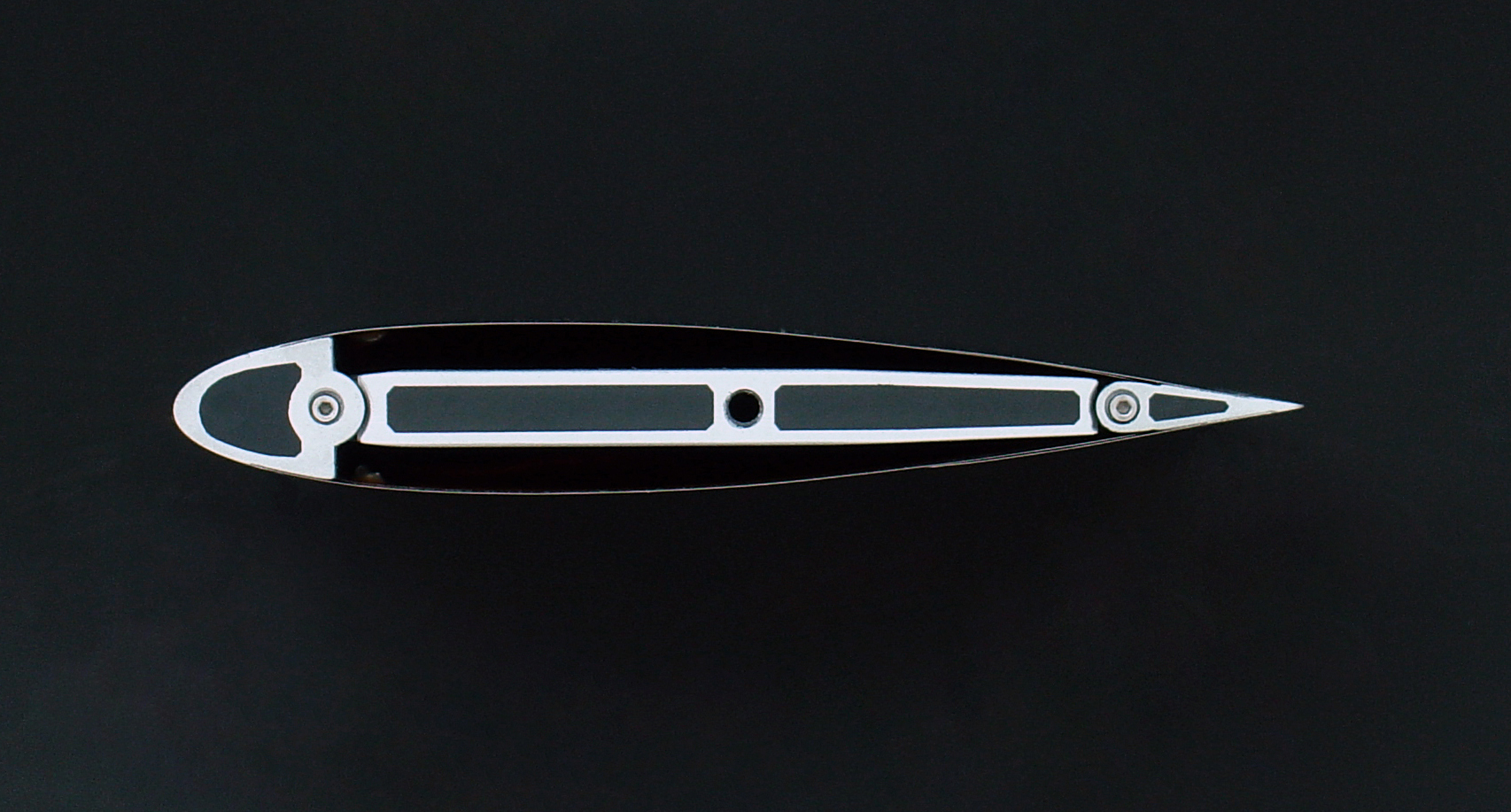

This research uses MFC actuators for changing the shape of aerofoils as required for improving their performance or reducing their undesirable aerodynamic characteristics. To this aim I have designed and constructed different aerofoil models with flexible skins whose shape can be changed by MFC actuators bonded to their inner side. Asymmetric (cambered) models have been initially used for testing the change of the shape of the upper skin only, Fig 2. |

|

| Figure 2: NACA 4415 aerofoil model for testing the shaping of the upper skin: assembled model (left) and inner side of the upper skin with MFC patches (right). |

The skin deflects inward when a positive voltage is applied to the MFCs, whereas it deflects outward when a negative voltage is applied, Fig. 3. The deflection causes the skin to have a small variation in the longitudinal direction which is accommodated by allowing it to slide in a thin pocket at the trailing edge. The geometry of the aerofoil without MFC actuation is close to that of the NACA 4415 type. |

|

| Figure 3: Schematic diagram of upper-surface actuation by MFC patches. |

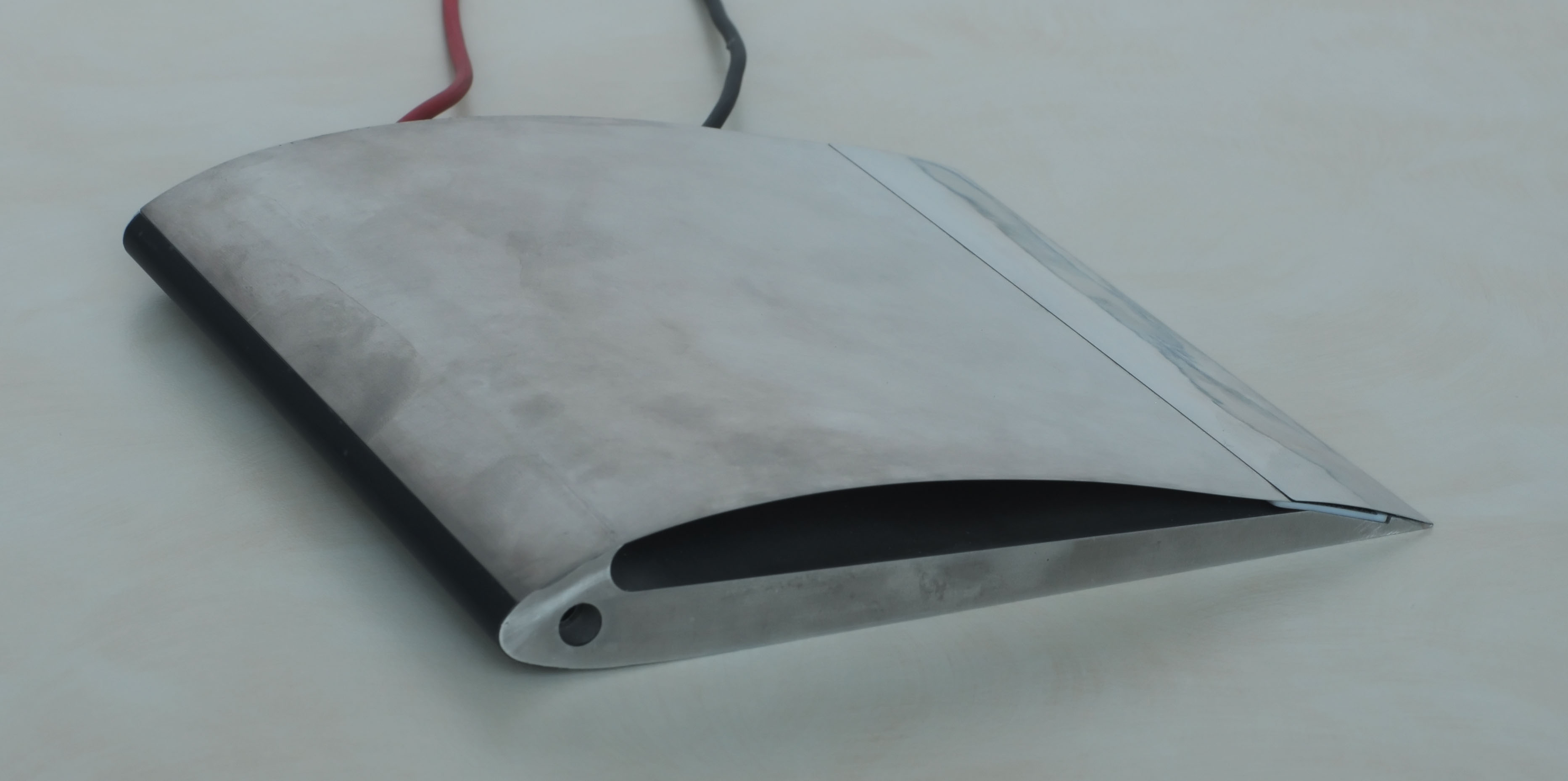

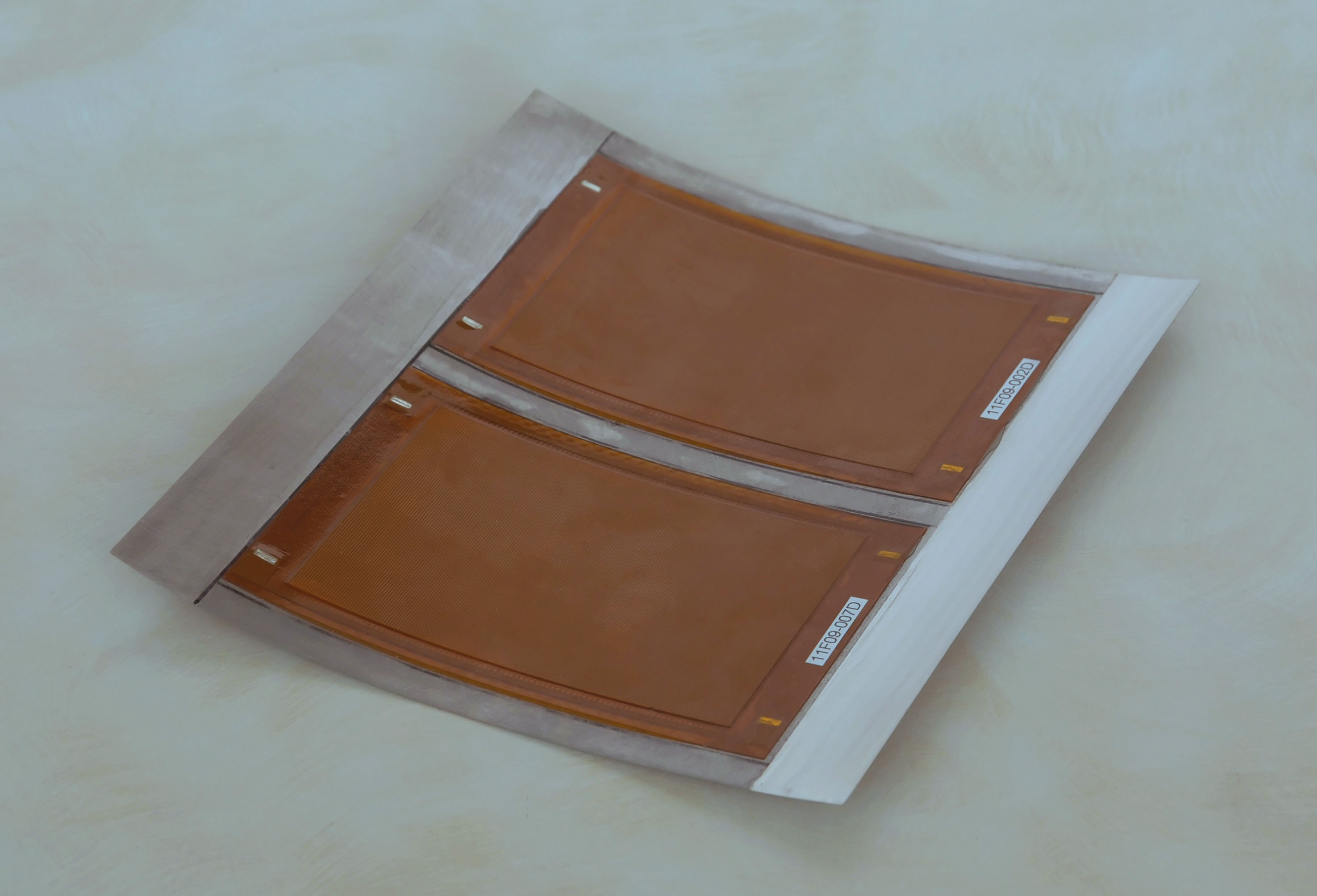

Symmetric aerofoil models have also been made that are capable of changing the shape of both the upper and the lower skins, Fig. 4. |

|

| Figure 4: NACA 0015 aerofoil model for testing the shaping of both the upper and the lower skins: assembled model (left) and inner side of one upper skin with MFC patches (right). |

Clicking on the following figure shows a movie of the model above which changes its shape and "dances" in a windtunnel (smoke is used to visualize the flow). |

|

| Figure 5: Aerofoil model performing an excerpt of the "Dance of the Flowers" from Tchaikovsky's The Nutcracker. |

Wind-tunnel measurements of these models have been taken at freestream velocities up to 15 m/s for values of the angle of attack ranging from -16° to 16°. In this range of velocities and angles of attack the skins of all the models did not exhibit any vibration or anomalous deformation and maintained a good response to actuation. |

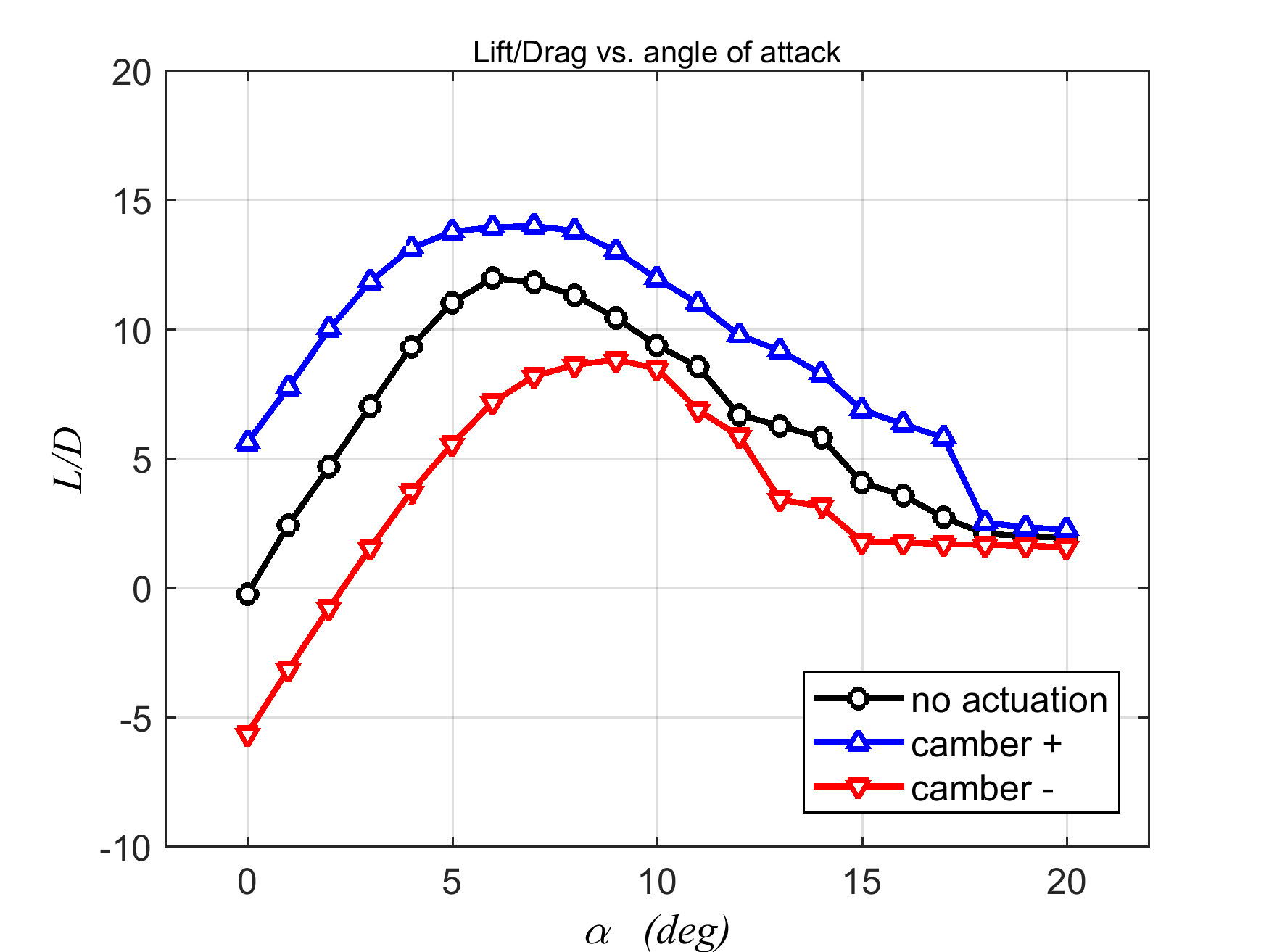

Figure 6 shows the lift over drag ratio of the model above. Changing the shape allows controlling the aerodynamic characteristics and larger values of the lift over drag ratio can be obtained by increasing the camber of the aerofoil at angles of attack typical of aircraft cruise conditions. The values for negative angles of attack can be obtained by mirroring the data of Fig. 6 about the two axes such that the data of the positive-camber case would mirror into the data of the negative-camber case, and vice-versa. |

|

| Figure 6: Lift over drag ratio of aerofoil model without actuation (symmetric) and with actuation to obtain positive and negative camber. |

Other aerodynamic characteristics, not shown here, indicate that such performance is achieved without deteriorating the static stability if applied to an aircraft. These data validate the idea that shaping an aerofoil by MFC actuators can be useful for tailoring or augmenting its aerodynamic performance. In particular, this technique could be very beneficial to broaden and stabilize the useful aerodynamic characteristics of high-performance aerofoils that quickly deteriorate at off-design conditions. The long term goal is developing smart wings and rotating blades capable of autonomous shaping for self-adjusting to changing flow conditions. |

Additional information on this research can be found in:

|

| MD current research | MD research | MD home |